Introduction

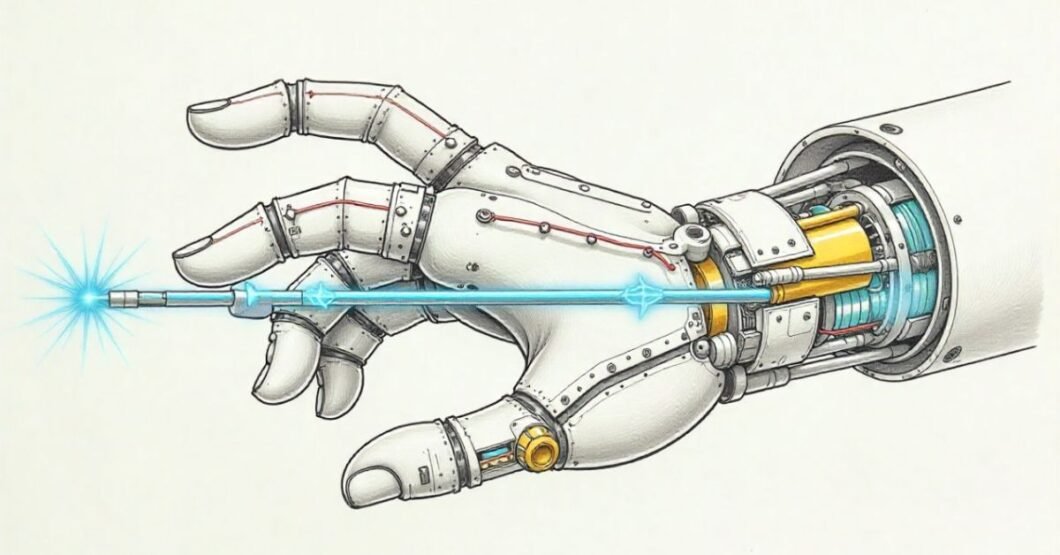

Engineers and researchers are still trying to find the perfect balance between accuracy, energy efficiency, and autonomy in the quest to create intelligent, low-power automation systems. Presenting Tribupneu, a cutting-edge approach to industrial control that combines pneumatic actuation and triboelectric sensing to enable machines to think and react without the need for external power sources.

In contrast to traditional motion systems that mainly depend on batteries or sophisticated electronics, it offers contact-activated intelligence that is self-powered and ideal for settings where energy supply is constrained or quick reaction is essential.

The technology, architecture, applications, and potential of Tribupneu are thoroughly examined in this essay, which also explains how this hybrid motion control model may change the direction of intelligent machines in the future.

What Is Tribupneu, and How Does It Work?

Tribupneu is a hybrid actuation technique that combines pneumatic logic systems with triboelectric nanogenerators (TENGs). Simply said, it makes it possible for intelligent mechanical actions, such as gripping, moving, and adjusting to be performed solely through tactile engagement, devoid of microcontrollers or connected electricity.

To put it simply:

- A little voltage is produced when electrons from two materials (such as copper and PTFE) come into contact and split.

- This voltage releases or routes compressed air by activating a pneumatic switch or relay.

- After that, the air pressure carries out a mechanical function (such as pushing, squeezing, extending, or stopping a part).

No batteries. Not a CPU. Movement is simply the result of material + pressure logic.

Because these systems are very sensitive and energy autonomous, they are especially helpful in wearable robots and remote operations.

The Evolution of Pneumatic Systems

For more than a century, pneumatics have driven industry. Compressed air is quick, safe, and reasonably priced for use in assembly robots and packaging lines. However, because it lacks the innate intellect that has historically been necessary:

- Different sensors

- intricate controllers

- Wiring that is heavy

A significant trend toward smart pneumatic control systems that respond contextually without requiring a computer is being driven by Industry 4.0 and artificial intelligence.

It bridges the gap by serving as the switch and sensor in a single move.

Core Innovations: Where Triboelectric Meets Pneumatics

Tribupneu is based on the combination of two scientific fields:

| Component | Function |

| Triboelectric Sensor | Generates voltage via touch/friction |

| Pneumatic Logic Circuit | Translates electrical charge into air-triggered motion |

| Elastic Substrate | Enables form-fit for wearables or soft tooling |

| Air Valves/Gates | Activated via tribo-input (no electronics required) |

One-touch mechanical intelligence, which is necessary for real-time tactile operations in wearables, robotics, and healthcare, is made possible by this synergy.

Tribupneu Architecture Explained

Tribupneu platforms employ distributed intelligence rather than a central brain, in contrast to conventional PLC-based (programmable logic controller) control systems.

Fundamental Layers of Architecture:

- Input Layer: Surface-applied triboelectric patches.

- Signal Layer: Signals are sent to air valves via conductive channels.

- Logic Layer: Using pneumatic logic gates to compress and vent.

- Actuation Layer: Air chambers or motors react immediately.

Chart: Signal-to-Actuation Time

| Action Type | Avg. Signal Delay | Energy Cost |

| Digital servo response | 100–200 ms | 12–20 J/action |

| Pneumatic via PLC | 80–100 ms | 15 J |

| Tribupneu via tribo | ~35–50 ms | <1 J (self-harvesting) |

Source: Tsinghua University’s Triboelectric Pneumatics Lab (2024)

Industrial Use Cases That Prove Scalability

When power, wiring, and delay are limited, tribupneu systems perform well.

Applications in the Real World:

- Soft robotics: Real-time touch-sensing and touch-responsive hands or tools.

- Wearable Exosuits: To aid in movement, tribopatches on the body activate pneumatic joints.

- Remote safety systems include gloves or helmets for miners that automatically make warning motions.

- Factory Line Tuning: Activating the air pusher after detecting a slippery object.

It gloves demonstrated 60% faster reaction movement in compressed-air tendons than wired microcontroller-based devices in recent tests conducted by the MIT BioMechanics Lab.

Benefits of Tribupneu Over Traditional Systems

| Feature | Tribupneu System | Traditional Pneumatics |

| Power Source | Self-generated (tribo) | External compressor + control |

| Response Time | Instantaneous | Moderate |

| Energy Consumption | Ultra-low | Medium to high |

| Complexity | Simple mechanical logic | Requires sensors + PLC |

| Maintenance Need | Minimal (no wires) | Regular service, replacements |

| Field Suitability | Harsh/Remote/Low-power | Needs stable infrastructure |

As a result, It reduces energy, cost, and cabling while increasing intelligence.

Tribupneu vs. Other Motion Technologies

What is the difference between Tribupneu and other intelligent motion control systems?

Key Technology Comparison

| Technology | Autonomous | Self-Powered? | Smart Logic | Edge Friendly | Use Cost |

| Tribupneu | ✅ | ✅ | ✅ | ✅ | 💰 Low |

| Servo Motors | ✅ | ❌ | ✅ | ⚠️ Partially | 💰💰💰 |

| PLC-Controlled Air | ❌ | ❌ | ✅ | ❌ | 💰💰 |

| IoT-Linked Actuators | ✅ | ❌ | ✅ | ✅ | 💰💰💰 |

It is the only truly autonomous mechanical actuation system without external power.

Challenges and Current Limitations

There is no such thing. Tribupneu too is troubled with:

- Material longevity: Triboelectric substrates are worn out due to frequent friction.

- Consistency of voltages: The levels of the output are sensitive to environmental considerations.

- Precision sequencing: Multi-gate logic in its infancy.

- Standards: Does not have any ISO certification for mass industrial deployment.

However, nanomaterials, airflow, and 3D-printed microfluidics are changing these shortcomings in the world very fast.

The Future of Autonomous Actuation

Tribupneu is a novel approach to machine interaction, not just a brilliant part.

Potential near-term outcomes include:

- AI-enabled air logic that modifies flow according to pressure behavior it has learned

- Stacking nano-layered substrates to increase signal voltage

- Real-time responsiveness through integration with prosthetics and surgical robotics

According to Soft Automation Association specialists, triboelectric or hybrid pneumatic-sensing logic will be used in 40% of wearable robots by 2028.

Getting Started with Tribupneu in 2025 and Beyond

Do you want to construct your first prototype or test?

Steps for Beginner Integration:

- Choose a TENG material and test silicone composites, PVDF, or copper.

- Utilize online CAD tools to design a single-gate pneumatic circuit, such as FluidSIM.

- Connect the tribo-output to preloaded air chambers or microfluidic systems.

- With a triggered action (touch → puff → motion), apply it.

- For early-stage builders, vendors such as TriboSense Labs, NanoPneu Tech, and OpenTENG.io provide easily available development kits.

Bonus: In 2026, the Global Pneumatic Alliance will host webinars and meetups on implementing self-powered movement technology.

FAQs

What is Tribupneu used for?

It is employed to create smart motion control solutions that work using air, without any special effort, and simply through natural touch.

Does wearable robotics have an insider with Tribupneu?

Yes. It is smooth, low-voltage, and the one that is safe in human-machine interaction.

Is Tribupneu an electronic-free worker?

That is its main advantage; it combines sensing and actuation with zero external circuits.

Who should use Tribupneu?

In robotics, prosthetics, remote tools, and low-power systems, this is ideal for engineers.

How can I test Tribupneu?

Request a dev kit or test containing a DIY air logic valve and triboelectric film containing a basic airflow setup.

Conclusion

Tribupneu makes it possible for an inexpensive, self-sufficient, and intelligent motion system to be used in actual industries as well as in laboratories. The paradigm is changing from controller-driven machines to machines that perceive and act on their own thanks to developments in material engineering, microfluidics, and decentralized automation.

You should give Tribupneu careful consideration if you’re developing wearable robots, smart devices, or autonomous tools.

To prototype a self-powered future, join a research team, go to a tech demo, or begin investigating open-source concepts.